Asia Continues Driving Sales for Engel

The number seven seems to be special for European plastics machinery makers at the moment — injection press giant Engel Holding GmbH said Oct. 15 that sales this year will likely go up 7 percent, the same increase that rival Wittmann Battenfeld GmbH projected a day earlier for its 2014 global sales.

Engel, which is the world’s largest injection molding machine maker based on sales, told a news conference at Fakuma 2014 in Germany that expansion in Asia is driving the jump this year, after its sales were down a nominal 1.5 percent in its last fiscal year.

“This 7 percent now comes mainly from our activities in Asia,” Engel CEO Peter Neumann told journalists. “For sure also our factories in Austria, they are running close to 100 percent utilization or even a little more.”

That would put sales for Schwertberg, Austria-based Engel at 1 billion euros in the fiscal year ending in March, up from 935 million euros in the 12 months ending in March 2014.

“All told, the global markets continue to be stable, even though political conflicts have weakened individual regions,” Neumann said, in a news release.

Russia, for example, has seen demand drop in half this year because of the crisis in Ukraine, but positive developments are expected in the next six months, Christoph Steger, Engel’s chief sales officer, said at the briefing.

Russia was Europe’s third-largest market for molding machines last year, with 1,500 units sold, Engel said.

Europe’s second-largest injection press market, Turkey, is showing positive signs and India is “slowly waking up again,” Engel said.

“China, the USA and Mexico continue to be Engel’s fastest-growing markets,” Steger said.

Engel said packaging and medical industry investments are strong among its customer end markets, while automotive is mixed — overall reinvestment continues to decrease slightly, but interest is high in innovation intensive areas like automobile lightweighting and plastic composite molding.

The 7 percent growth estimates from Engel and Wittmann Battenfeld, both Austrian firms, is significantly better than the 3 percent increase in plastics and rubber machinery sales projected for this year for German manufacturers by the German machinery trade association VDMA.

Engel told journalists it has steadily gained market share in Europe, increasing from just under 20 percent of the injection press market in 2007 to a little over 30 percent last year.

At the fair, the company was touting a number of new products and technology, and seemingly making efficiency the word of the week at its stand.

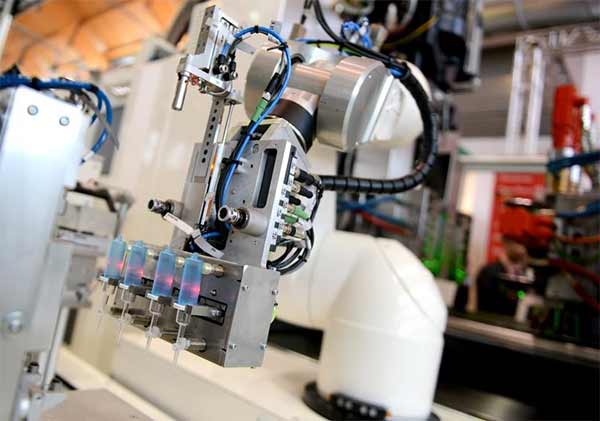

The company, for example, introduced a new line of standardized “pick and place” robots designed to work with smaller machines. The new “e-pic” line of robots requires half the energy of linear robots of the same size, Engel claimed.

It also introduced an improvement to its “flomo” line of flow controllers that allow for automated adjustments of water used in mold temperature control, unveiled a new design for one of its duo line of injection molding machine with improved ergonomics, and it gave its viper robot line a technical makeover to better adopt its new CC300 control unit.

One aspect of machinery on display is combining different process technologies. The company is using a duo 550-ton injection molding machine with an integrated viper 20 robot, and incorporating both its Engel foammelt process (using the Mucell foam technology) and variothermal injection molding to make a center console for a car from polycarbonate/ABS.

“For the first time, this will enable us to produce thin-walled parts with very high-quality surfaces and excellent fine structure reproduction at the same time in a single injection molding step,” said Franz Füreder, vice president of automotive business at Engel.

The variothermal process came from French manufacturer Roctool. While the booth was displaying an automotive part, Engel believes it can be used in appliances and household products.

It expanded the tonnage range of its e-motion tie-barless technology, unveiling a 50-ton all-electric drive e-motion 50 TL, which was making a plug housing from fiberglass-reinforced PBT/ASA at the booth.

Engel said the smaller machine has a one-piece machine frame to make the machine lighter and more compact, and said the technology was targeted at the teletronics market, where space and precision molding are important.

“The trend toward ever higher productivity per square meter of factor space is continuing,” said Heinz Rasinger, vice president of Engel’s teletronics business. “The electronics industry also has extremely high demands as regards precision.”

The Schwertberg, Austria-based machine maker was using Fakuma to give its tie-barless technology a 25th birthday party.

Engel introduced the tie-barless injection molding machine at K 1989, and said it’s been one of the company’s biggest revenue streams, with more than 60,000 units sold.

That’s in part because the technology allows smaller, less energy-intensive machines to mold a job that typically would require a larger machine with tiebars, Engel said.

As an example, at the show the company was molding a pipe fitting on an 80-ton Victory model tie-barless machine, but it said typically a 150-ton machine would be needed.